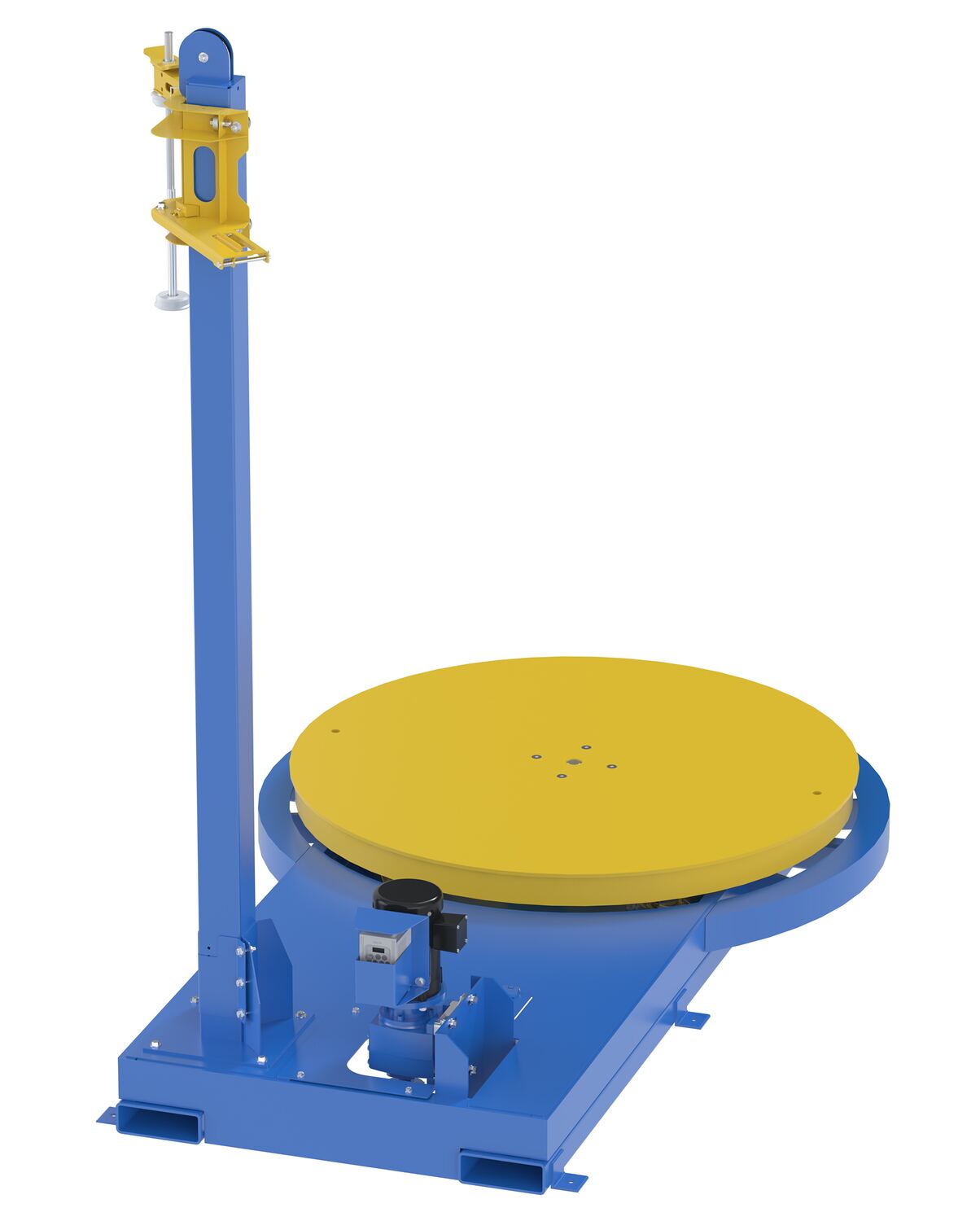

Proper stretch wrap machine repair helps prolong the lifespan of your machinery.

Proper stretch wrap machine repair helps prolong the lifespan of your machinery.

Blog Article

Specialist Tips to Make Sure Effective Stretch Cover Equipment Repair Work Practices

When it pertains to extend wrap maker repair work, knowing the usual concerns that can arise is vital. You'll intend to be geared up with the right tools and a clear troubleshooting process to tackle issues successfully. Normal maintenance can not be neglected either, as it plays an essential function in avoiding bigger issues down the line. Allow's explore these vital areas to guarantee your fixing methods are as effective as possible.

Recognizing Common Stretch Wrap Device Issues

When you use a stretch wrap device routinely, it is essential to recognize typical issues that can emerge. One regular trouble is inconsistent tension in the film, which can lead to loose or extremely limited wraps. You'll intend to inspect the stress setups frequently to confirm they're calibrated correctly. One more usual concern is movie sticking or tearing, frequently brought on by improper loading or worn-out components. If you observe this, check the film path and replace any type of damaged parts. In addition, expect mistake messages or unusual noises throughout operation; these can suggest mechanical breakdowns. Obstructing is one more frustration, normally stemming from particles or misaligned rollers. Routinely clean the machine and verify all parts are straightened to stop this. By staying in advance of these concerns, you can keep your stretch wrap maker running efficiently and successfully, lowering downtime and maintaining efficiency in your procedures.

Crucial Devices for Effective Repair Work

To properly repair a stretch cover maker, having the right tools on hand is important. These will certainly help you tackle most mechanical concerns.

Don't forget safety and security equipment, such as gloves and safety and security goggles, to protect yourself while working. An excellent flashlight is necessary, as well, as it helps light up tight spaces where you may require to check components.

Furthermore, keep a toolkit with spare parts like belts, rollers, and merges. These can conserve you time throughout repair work, permitting you to replace damaged components instantly. A service guidebook specific to your equipment will give assistance and schematics, making repairs much more simple. With these vital tools, you'll be well-appointed to manage any kind of repair service obstacle that comes your way.

Step-by-Step Troubleshooting Guide

When troubleshooting your stretch wrap device, it's important to begin with a review of usual concerns you might deal with. By using the appropriate diagnostic tools, you can promptly identify the origin of the issue. Let's stroll via a detailed guide to obtain your equipment back up and running effectively.

Common Issues Summary

While stretch cover makers are essential for reliable packaging, they can encounter a range of problems that disrupt procedures. One typical trouble is irregular film stress, which might lead to loosened or extremely limited wraps. If you observe this, check the tension setups and make certain the film is packed correctly. Another issue is film tearing during the covering procedure; this commonly comes from plain cutting blades or inappropriate movie alignment. On a regular basis check and replace blades as required. Furthermore, if the maker will not start, confirm that all safety switches are involved and the power supply is operating. Be alert for uncommon noises, which might suggest mechanical wear that requires immediate focus. Dealing with these issues quickly can conserve you time and sources.

Analysis Tools Use

Efficient repairing begins with the right analysis tools at your disposal. Begin by collecting essential tools like multimeters, thermal video cameras, and stress gauges. stretch wrap machine repair. Each device serves a specific objective in identifying issues

First, utilize a multimeter to inspect electrical links and assurance power streams properly. Next, employ a thermal video camera to find overheating components, which can indicate failings. Use a stress scale to keep an eye on pneumatically-driven systems for leakages or variances.

Don't hesitate to consult your maker's guidebook for details troubleshooting steps connected to the version. With visit our website these tools and a systematic approach, you'll successfully diagnose and deal with machine issues.

The Value of Normal Maintenance

Regular maintenance is important for maintaining your stretch cover equipment running smoothly and effectively. By scheduling preventative upkeep, you can capture prospective concerns prior to they rise, conserving you time and cash. Remaining on top of upkeep periods assurances your devices remains in leading shape and decreases unforeseen downtime.

Preventative Maintenance Conveniences

When you focus on preventative upkeep for your stretch wrap maker, you not only expand its life expectancy yet additionally improve its efficiency. Normal checks aid determine possible concerns before they rise into costly repair work. By maintaining components clean and moisturized, you ensure smoother procedure, which can cause far better wrapping top quality and decreased material waste.

Furthermore, a properly maintained equipment runs with fewer disturbances, decreasing downtime in your assembly line. You'll likewise discover that regular maintenance can increase employee morale, as they can count on equipment that does constantly. Lastly, remaining proactive with upkeep can boost your general return on investment, allowing you to allot resources extra successfully. Accept preventative maintenance, and see your procedures prosper.

Scheduled Maintenance Intervals

Although it may be tempting to skip maintenance checks, sticking to arranged maintenance periods is vital for keeping your stretch cover device running smoothly. Regular maintenance helps you recognize possible concerns prior to they escalate into costly repairs. By adhering to a set routine, you ensure that all essential components obtain the focus they require, avoiding unexpected breakdowns and downtime.

Investing time in scheduled maintenance not only prolongs your machine's life-span but also improves performance in your procedures. Remain proactive, and your stretch cover device will thank you!

Security Protocols During Repair Job

To secure a risk-free fixing setting, it is important to follow well established security procedures. Constantly use the ideal personal protective devices (PPE), including gloves, security goggles, and steel-toed boots. Before beginning any why not try here work, confirm the maker is powered down and secured out to stop unexpected start-ups. Familiarize on your own with the device's technical documents and safety and security cautions; this understanding can avoid unsafe errors.

Training and Skill Development for Technicians

Effective training and skill advancement for specialists are important in making certain successful stretch wrap device repairs. You need a strong understanding of the machine's components and just how they operate with each other.

Motivate constant education by attending workshops and seminars concentrated on the most up to date technologies and fixing methods. This maintains you upgraded on market trends and helps you adopt best methods. Pairing experienced professionals with novices fosters a discovering atmosphere where skills can be shared and established.

Lastly, apply a mentorship program to guide less experienced professionals, guaranteeing they obtain the confidence and knowledge needed for efficient repairs. Purchasing training and skill development not just boosts repair work high quality but likewise enhances the general efficiency of your procedures.

When to Look For Specialist Help

Recognizing when to seek professional aid can conserve you time and protect against further damage to your stretch wrap device. If you notice persistent issues like uncommon sounds, inconsistent wrapping, or error messages that you can not troubleshoot, it's ideal to contact a specialist. Do not disregard small problems, as they can escalate into expensive repair services if left unaddressed.

In addition, if you have actually already tried repair work however have not seen improvement, it's a clear indicator that expert treatment is necessary. Dealing with complicated systems without the appropriate competence can cause more significant failures.

Often Asked Inquiries

How Commonly Should Stretch Cover Machines Be Serviced?

You ought to service stretch cover devices every six to twelve months, depending upon usage. stretch wrap machine repair. Regular upkeep stops break downs, enhances performance, and prolongs the maker's lifespan, guaranteeing you get the most out of your investment

What Are the Indicators of a Stopping Working Stretch Wrap Equipment?

You'll notice a stretch cover device is failing if it produces inconsistent wraps, makes uncommon noises, or reveals mistake messages. Additionally, constant jams or slow-moving operation can show underlying problems requiring prompt focus and repair service.

Can I Fix My Equipment Without Prior Experience?

You can try to repair your machine without prior experience, yet it's high-risk (stretch wrap machine repair). You could encounter obstacles understanding components or diagnosing concerns. Consider looking for assistance or specialist help to avoid additional damage and guarantee effective repair work

What Is the Typical Life-span of a Stretch Wrap Equipment?

The standard life-span of a stretch wrap device is commonly around 5 to 10 years, depending upon use and upkeep. Normal upkeep can extend its life, ensuring you get the most out of your investment.

Exist Details Brands Recognized for Better Dependability?

Yes, some brand names like Aetna and Lantech are understood for their integrity. You'll locate that purchasing well-reviewed equipments usually brings about less upkeep issues and longer life expectancy, saving you time and prices over time.

Conclusion

By focusing on upkeep, utilizing the right tools, and complying with a methodical troubleshooting guide, you can boost your stretch cover equipment fixing techniques. Bear in mind, normal evaluations and documents help capture issues early, while sticking to safety methods maintains you and your group risk-free.

Report this page